‘Green’, or zero-carbon hydrogen, produced directly from water using renewable electricity, will play a central role our sustainable energy future.

By Kevin Fothergill, Chief Executive, EnAcumen Ltd

Hydrogen from water

The production of hydrogen from water is not new. The process of electrolysis was first demonstrated at the beginning of the 19th century by William Nicholson and Anthony Carlisle when they passed an electric current through water and produced bubbles of hydrogen and oxygen. Since then, this remarkable discovery has only found limited use, mainly because it has been cheaper to produce hydrogen from fossil fuels such as natural gas. Currently only 0.1% of hydrogen is produced by water electrolysis (1), but this is about to change.

The Hydrogen Council, which represents members with a combined revenue of €18 trillion, predicts that by 2030, more than 7 million tonnes of ‘green’, or zero-carbon hydrogen, will be produced by electrolysis using surplus renewable electricity (2). This is equivalent to one day of the world’s total final energy demand and presents an enormous economic opportunity for companies involved in the value chain for electrolysis and green energy. By 2050, they predict that that number will double.

Hydrogen comes in many colours

Approximately 70 million tonnes of hydrogen are produced each year, and almost all of this comes from natural gas or coal.

Unfortunately, the extraction of hydrogen from fossil fuels, results in the release of 830 million tonnes of carbon dioxide (CO2) into the atmosphere each year. Hydrogen produced this way is known as ‘brown’ or ‘grey’ hydrogen. New processes are being developed to enable about 85% of this CO2 to be captured and stored, providing low-carbon, or “blue” hydrogen which although not perfect, is a big step forward.

The world has huge natural gas resources and forecasts suggest that it will continue to be both readily available and cheap for decades to come (3). It is inevitable, therefore, that natural gas will continue to provide a large proportion of our energy needs. As we transition to a more renewable, low carbon energy system, the carbon in this natural gas will be extracted and stored and the resulting blue hydrogen will substitute natural gas as a fuel for heat and power generation. Studies are underway in the UK to shown that up to 20% of hydrogen can be added to the natural gas grid without affecting the cooking and heating appliances that we currently use (4). This part of a larger initiative which could see the complete conversion of the gas network to 100% hydrogen in support of the UK Government’s net zero target for 2050.

Electricity demand will increase

Whilst carbon capture and storage (CCS) will mean that we can continue to use existing, finite resources for transport and heat, electrolysis has a key role in integrating renewable electricity generation into all aspects of the energy system. We are seeing increasing amounts of renewable energy injected into the electricity grid, displacing the electricity that we would have previously produced by burning fossil fuels. The result is a progressive decarbonisation of the electricity that we use. The further opportunity to use renewable electricity to power cars and some other vehicles means that our demand for electricity overall will increase substantially as we use less and less petrol and diesel.

This is great news for global warming but there are some challenges that need to be addressed. One of these is the need to balance the amount of renewable electricity, which is generated at any point in time, with the demand for electricity which is dictated by the needs of industry and consumers. This challenge becomes harder as the intermittent, renewable proportion of our electricity supply increases and as overall demand for electricity also increases.

Large amounts of renewable electricity will need to be stored for a rainy, or at least windless, day

To some extent we can manage supply and demand by turning down production or encourage (in effect pay!) end-users to reduce demand at certain times. This can contribute, but ultimately, we will need to be able to store large amounts of electricity when generation exceeds demand and release electricity from storage when demand exceeds supply. This is where electrolysis comes in.

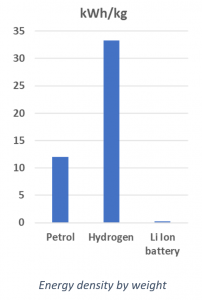

Small amounts of electricity can be stored in batteries, and they are ideal for some applications, but they are not the best technology for storing large amounts of energy. The best batteries available today can store around 0.3 kilowatt hours (kWh) per kilogram of battery (5). For comparison, the energy stored in 1kg of petrol is equivalent to 12.3 kWh and hydrogen holds 33.3 kWh per kg (lower heating values).

Because the amount of energy a battery can store is directly related to the amount of solid storage material (e.g. lithium) it contains, large batteries can be very expensive. On the other hand, hydrogen, which is a gas, only requires an empty space in which to contain it and for the storage of large amounts of energy this makes it more cost effective. There are other factors to take into account, such as efficiency losses in the production of hydrogen by electrolysis and the costs of compressing it, but overall, it is widely agreed that hydrogen is the preferred option for storage of very large amounts of energy.

The future energy system

The future energy system will consist of large-scale renewable electricity generation, which in Northern Europe will be mainly from offshore wind. This will supply the electricity grid directly until the amount of electricity being generated exceeds supply, at which point, the surplus will be used to produce hydrogen from water by electrolysis. The hydrogen will be stored underground in purpose-built caverns or in depleted natural gas wells. Caverns, constructed in salt deposits in the UK at Teesside, have already been used for the storage of large quantities of hydrogen (6). Some of this hydrogen will be used directly as a fuel – it can be burned cleanly without any CO2 produced, or it can be used in a fuel cell to generate electricity and heat with very high levels of efficiency. Although burning hydrogen can still produce some pollutants such as nitrogen oxides because these are formed when nitrogen and oxygen in the air are exposed to high temperatures, fuel cells can operate at low temperatures producing only water as a by-product.

These fuel cells can be installed in cars, buses, trains or ships for transport or they can be used to (re)generate electricity when demand exceeds supply, providing a means of balancing the electricity grid.

The status of electrolysis

There are two types of electrolyser that have reached a level of commercial maturity. These are the ‘alkaline’ and ‘PEM’ (proton exchange membrane) technologies. Each has its strengths and weaknesses and it is likely that both types will share the market for some time to come.

Other new technologies are in development and the most promising of these is ‘solid oxide’ electrolysis. This operates at high temperature and has some potential benefits such as improved efficiency and lower costs.

The widespread adoption of green hydrogen as a fuel will only occur if it can be produced and sold profitably. The price that end-users will pay is determined, to a certain extent, on the costs of that they already incur when using a conventional fuel. There may be some premium chargeable due to its green credentials but it is fair to say that the cost of green hydrogen is currently far higher than it needs to be in the longer term.

Partly, this is due to scale. Electrolysers need to be scaled-up and produced in larger numbers to reduce their manufacturing costs. There is also a need for more R&D to reduce the costs of the materials used, some of which are very expensive, and to improve the productivity of the equipment; that is, to increase the amount of hydrogen that can be produced from a system of a given size.

By far the largest factor affecting the cost of green hydrogen is the cost of the renewable electricity that is used. In 2019, the average price for ‘extra-large’ non-domestic consumers in the UK was 10.5p/kWh (7). A price of 2-3p/kWh will be needed for widespread use of green hydrogen for heat and electricity generation. This is not unachievable. About half of the 10.5p/kWh is due to network and distribution costs and these can be substantially avoided if large-scale electrolysers are connected ‘behind the meter’, directly to renewables. Furthermore, as the proportion of renewables increase, low cost (even free), surplus electricity can be used to generate hydrogen.

In summary, electrolysis will play a vital role in the future energy system. The technology is advanced but needs further development and it will rely on the availability of low-cost renewable electricity.

Further details on electrolysis in the future energy system is available from EnAcumen Ltd.

References

- International Energy Agency. The Future of Hydrogen. s.l. : International Energy Agency, 2019.

- The Hydrogen Council. Hydrogen Scaling Up. s.l. : The Hydrogen Council, 2017.

- DNV GL. Energy Transition Outlook 2017, Oil and Gas Forecast to 2050. s.l. : DNV GL, 2017.

- Hydeploy: The UK’s First Hydrogen Blending Deployment Project. Isaac, T. 2, s.l. : Clean Energy, 2019, Vol. 3.

- The Faraday Institution. Faraday Report – January 2020, High Energy Battery Technologies. s.l. : The Faraday Institution, 2020.

- H21 Leeds City Gate Team. H21 Leeds City Gate Project Report. s.l. : H21 Leeds City Gate Team, 2019.

- ofgem. State of the energy market 2019 report. 2019.